Want to protect the environment? Choose the right absorbents.

Uncontrolled leaks can occur during operations, such as during production, transport or treatment of various liquids.

How do you choose the right absorbents? How do you recognise the products; and what are the specifications you need? This Selection Aid is designed to help you decide which absorbents your company needs, the questions you should ask yourself, the different absorbent types, and the different benefits and features. There are many aspects to consider depending on the liquid type, amount, and zones; you do not want to choose an absorbent product randomly.

Absorbents prevent dangerous or chemical products finding their way into the ground. Kruisinga offers a suitable absorbent for every application. You can read all about this below.

How do you know which absorbents your company needs?

Have you accidentally spilled chemical products, or have you suffered a leak of some form of liquid such as petrol or oil? Then choose your absorbent. These agents have been specially developed to protect the environment and people against chemical agents. Do you want to purchase or use absorbents after an incident? Then you first need to know the type of absorbent your company needs.

Ask yourself the following questions

To find out which absorbent is most suitable for your company, you need to know the activities of your company and what products can be found in the rooms. First of all, you can ask yourself questions to find out which absorbents your company needs. Examples of these are:

-

- - What fluids are used within the company? There are different types of absorbents for various liquids.

- - How much liquid could be spilled? This is useful to know to estimate the size of the absorbers.

- - Which zones need to be protected?

- - In which room types are the substances used?

- - What accidents have occurred in the past, and which absorbents did you need at them time but were not available?

In addition, it is important to monitor your stock levels. This will prevent you from unexpectedly running out of absorbents.

Which absorbent colour matches which liquid?

Gray: all liquids

Blue: oil and hydrocarbons and water repellent

White: oil and hydrocarbons and water repellent

Yellow: Chemicals

Which absorption for which application?

Absorbents exist in several forms and types. Each has specific properties that have been developed for a specific application. The choice depends on the type of liquid to be absorbed.

Absorption pads

Absorb small volumes on small surfaces, under leaking machines, on retention floors, for prevention during disassembly, on work conveyors and workplaces, laboratory tables, during maintenance work, remediation of water surfaces, etc.

Absorption rolls

Absorption rolls allow you to absorb large volumes on large surfaces or around machines, or make walkways safe.

Absorption Hoses

Confine and absorb flow zones, contain an accidental spill, and prevent liquid from spreading.

Absorption cushions

Absorb large amounts of liquid in a small area.

Absorption barrel mats

Absorb drips on 60 or 200 litre barrels.

Absorption weeps

To remove oil films from a water surface

*Available on request; please contact us, we would be happy to discuss the possibilities.

Absorption booms

Contain and absorb contamination on a water surface.

*Available on request; please contact us, we would be happy to discuss the possibilities.

Absorption flakes

To remove discharged hydrocarbons in hard-to-reach places.

*Available on request; please contact us, we would be happy to discuss the possibilities.

Features and benefits

Absorption materials have various features; a short explanation of these can be found below.

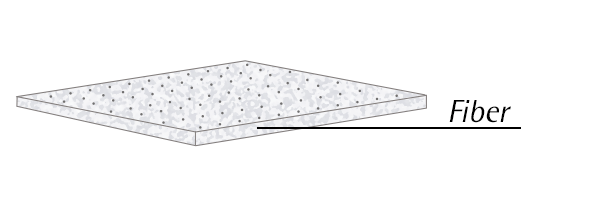

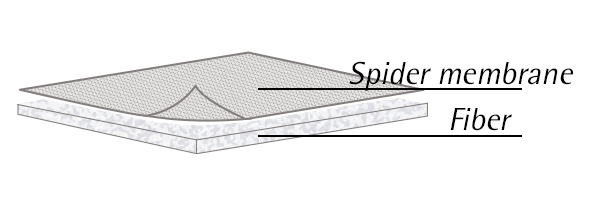

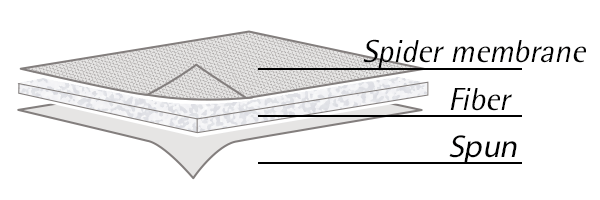

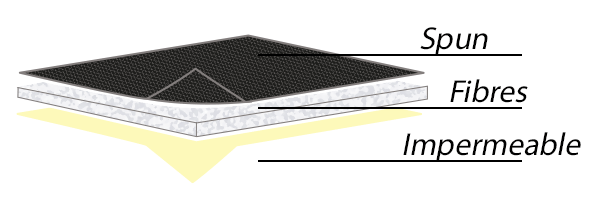

Fibres: polypropylene, absorbent fabric.

Spunbond: reinforcement fleece, anti-piling and better resistance.

SMF spun: fleece for extra reinforcement, high mechanical resistance.

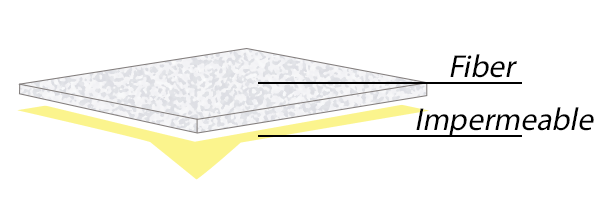

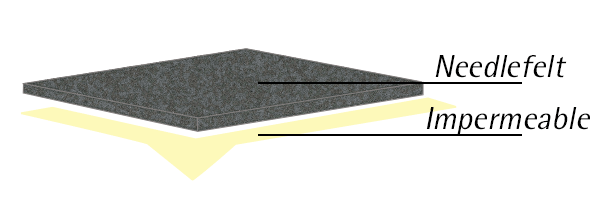

Impermeable layer: avoids any contact with the soil and is slip resistant.

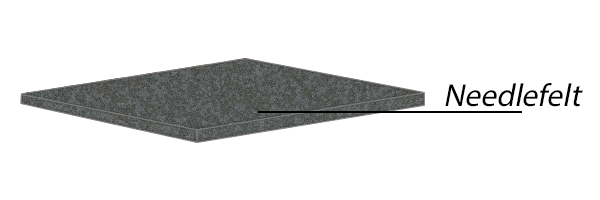

Needle felt: polyester, very high mechanical resistance.

Various layer structures

Perforated or unperforated?

Industry range: Perforated

For efficient use, perforated products can be torn down to smaller usable sizes for smaller spills.

Remediation range: Unperforated

Mainly used to remove oil from a water surface.

Single or double thickness?

Single thickness

Standard absorbency. Prevention, drip level

Double thickness

Higher absorbency and larger volumes.